Operated by the 846th TS, the HHSTT is the world's premier rocket sled test track. The mission of the 846th TS is to plan and execute world-class rocket sled tests enabling critical weapon system development in support of the warfighter using world-class people, technical excellence, cost-effectiveness and agility.

At 59,971 feet, the HHSTT is the longest facility of its type in the world. Each of the three rails that form the track is continuously welded, in tension at temperatures below 120º F, and aligned to within 0.04 inches of intended position in the operational region of the track. The HHSTT serves as a critical link between laboratory-type investigations and full-scale flight tests by simulating selected portions of the flight environment under accurately programmed and instrumented conditions, often before flight-worthy hardware is available.

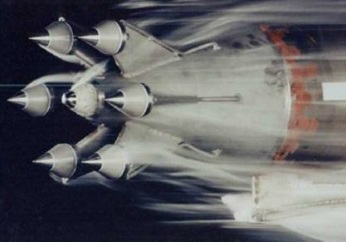

Test vehicles (sleds) are accelerated to mission velocities by means of solid rocket motors, frequently in multi-stage operation. Sled speeds in excess of 9,400 feet per second have been demonstrated in the past and the 846th TS is pursuing an on-going improvement program to achieve speeds in excess of 10,000 feet per second in support of future customer requirements. Sleds weighing up to 60,000 pounds have been used and heavier sleds can be operated if required. Depending on payload size, instantaneous accelerations of more than 200g have been demonstrated. For a wide range of test problems, the HHSTT provides and efficient, safe and cost-effective ground test alternative to expensive developmental flight tests.

Complementing the Test Track itself, the overall HHSTT complex encompasses ancillary facilities for artificial rain simulation, an accurately surveyed ejection test area, captive and free-flight blast test sites, impact test sites and a horizontal rocket test stand. Support facilities include buildings for electronic and photo-optical instrumentation, a telemetry ground station and engineering and shop facilities for design and fabrication of test hardware.

| Bridges the gap between laboratory and flight tests. |

| Allows full-scale high-fidelity testing. |

| Lower cost than flight testing. |

| Post-test recovery of test hardware. |

| Hypersonic Velocity |

| Munitions: Hard Targets, Penetrator Effectiveness, Missile Defense, Fuzing, Dispenser, Seekers, Guidance, Warhead Lethality. |

| Crew Escape: Ejection Seats, Parachutes, Canopies, Vulnerability, Rocket Catapults and Ejection Seats and Safety & Survival Equipment. |

Impact testing of warheads, seekers and fuzes; hard target and earth penetrators.

Weapons dispensers and missile launchers.

Simulated rain field or individual droplet impacts

Ice, dust and particle impacts; full-scale nosecones or multiple material samples

Full-up escape system evaluation.

Multi-Axis Seat Ejection Sled - One-of-a-kind sled capable of ejections

at +30º pitch, +20º yaw, +90º static roll or 360º per second dynamic roll.

| 846th Test Squadron |

| 575-679-2133 / DSN 349-2133 |

| 575-679-2766 / DSN 349-2766 |